Aluminium 5083 is known for exceptional performance in extreme environments. 5083 is highly resistant to attack by both seawater and industrial chemical environments.Alloy 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65°C.

| Element | Composition % |

|---|---|

| Manganese (Mn) | 0.40 - 1.0 |

| Iron (Fe) | 0.00 - 0.40 |

| Copper (Cu) | 0.0 - 0.10 |

| Magnesium (Mg) | 4.0 - 4.90 |

| Silicon (Si) | 0.0 - 0.40 |

| Zinc (Zn) | 0.0 - 0.25 |

| Chromium (Cr) | 0.05 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

| Property | Value |

|---|---|

| Proof Stress | 115 Min MPa |

| Tensile Strength | 270 - 345 MPa |

| Elongation at 50 mm | 15 Min % |

| Hardness Brinell | 75 HB |

| Bend Radius 90° | 2.5 x t |

| Please note that Mechanical Properties shown are for H111 temper | |

| Property | Value |

|---|---|

| Proof Stress | 215 Min MPa |

| Tensile Strength | 305 MPa |

| Elongation at 50 mm | 15 Min % |

| Hardness Brinell | 85 HB |

| Bend Radius 90° | 3.5 x t |

| Please note that Mechanical Properties shown are for H116 temper | |

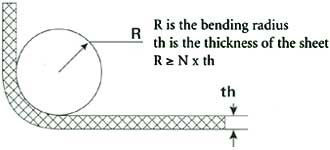

Aluminium Alloy 5083 is capable of being bent cold through an angle of 90 degrees around a pin having a radius equal to N times the thickness (t) of the sheet without cracking.

One of the key factors to consider when working with marine grade Aluminium is the minimum bend radius. This refers to the smallest radius that the metal can be bent without cracking or damaging the plates. When the metal is bent beyond its minimum bend radius, the stress on the material becomes too great and it can begin to crack or break. To prevent this and maintain the structural integrity of marine grade Aluminium, it is important to adhere to the recommended minimum bend radii for the specific alloy, temper and thickness of aluminum being used.

| Property | Value |

|---|---|

| Density | 2.65 g/cm3 |

| Melting Point | 570°C |

| Thermal Expansion | 25.0 ×10−6 /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 0.058 ×10−6Ω.m |

With multiple warehouse locations in Abu Dhbai, Dubai & Sharjah, we ensure speedy deliveries to our customers all across the uae