Aluminium 5052 is known for its great workability allowing tight bend radii of 1.5T, it is a high strength non heat treated alloy and is corrosion resistant which makes it ideal for manufacturing of outdoor enclosures

| Element | Composition % |

|---|---|

| Manganese (Mn) | 0.0 - 0.10 |

| Iron (Fe) | 0.00 - 0.40 |

| Copper (Cu) | 0.0 - 0.10 |

| Magnesium (Mg) | 2.2-2.8 |

| Silicon (Si) | 0.0 - 0.25 |

| Zinc (Zn) | 0.0 - 0.10 |

| Chromium (Cr) | 0.15 - 0.35 |

| Aluminium (Al) | Balance |

| Property | Value |

|---|---|

| Proof Stress | 160 Min MPa |

| Tensile Strength | 215 - 265 MPa |

| Elongation at 50 mm | 12 Min % |

| Hardness Brinell | 61 HB |

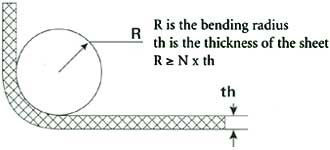

| Bend Radius 90° | 1.5 x t |

| Please note that Mechanical Properties shown are for H32 temper | |

Aluminium Alloy 5052 is capable of being bent cold through an angle of 90 degrees around a pin having a radius equal to 1.5 times the thickness (t) of the sheet without cracking.

| Property | Value |

|---|---|

| Density | 2.68 g/cm3 |

| Melting Point | 608°C |

| Thermal Expansion | 23.70 ×10−6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 138 W/m.K |

| Electrical Resistivity | 0.0495 ×10−6Ω.m |

With multiple warehouse locations in Abu Dhbai, Dubai & Sharjah, we ensure speedy deliveries to our customers all across the uae